What is Solder Wire? Step-by-step guide to using solder wire efficiently

Nội dung bài viết

- What is solder wire?

- Different types of Solder Wire

- Advantages of Solder Wire

- Step-by-step guide to using Solder Wire efficiently

- How to choose the right Solder Wire

- Common mistakes to avoid when selecting Solder Wire

- Applications of Solder Wire

- How to maintain Solder Wire for long-term use

What is solder wire?

Soldering also known as welding, is a time-honored method used to connect metal parts. The process involves heating the metal usually with a flame or another source of high temperature until it becomes liquid. Once the metal is molten, the two surfaces can be joined together without the need for adhesives, as the heat allows them to bond naturally. To ensure a stable and lasting joint, the metals must be compatible with each other, particularly when exposed to heat in an environment containing oxygen, which could trigger undesirable chemical reactions.

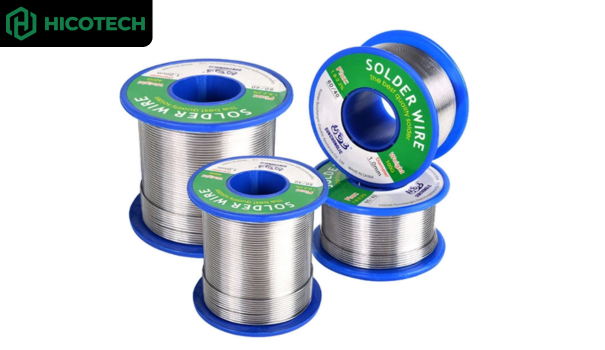

Among the various materials used in this process, solder wire stands out as one of the most widely used and important. It is essential for creating strong, durable connections and meeting strict technical requirements. This article highlights the benefits of solder wire, the different types available, and how to choose the most suitable option for specific applications.

Different types of Solder Wire

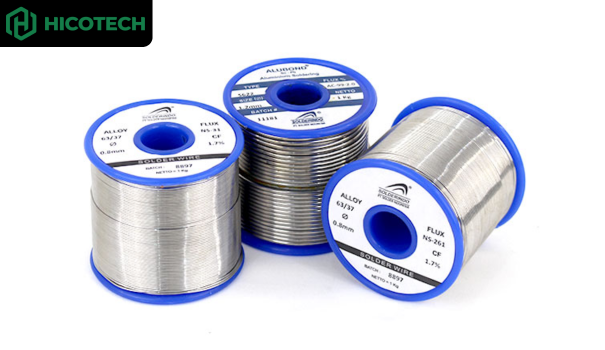

Leaded solder wire

Leaded solder wire is primarily composed of a tin-lead alloy, with a 60/40 ratio (60% tin and 40% lead) being the most commonly used formulation. This specific composition results in a relatively low melting point of approximately 183-190°C (361-374°F), allowing for quick and efficient heat application during the soldering process. The presence of lead offers several advantages, such as excellent wettability and the ability to produce smooth, shiny solder joints. Due to its softness, this type of solder wire is best suited for applications where mechanical stress is minimal.

However, concerns over the health and environmental risks associated with lead have led to increasing restrictions on its use. Regulatory frameworks, such as the European Union's RoHS directive, have phased out lead-based solders in consumer electronics and other sectors. As a result, manufacturers like Sonic Solder Wire, Inc. have been transitioning toward lead-free alternatives to comply with global safety and sustainability standards.

Lead-free solder wire

The adoption of lead-free solder wire has grown significantly, driven by environmental regulations and the global shift toward safer and more sustainable manufacturing practices. One of the key ecological benefits of lead-free solder is its ability to reduce the environmental and health risks traditionally associated with lead-based materials. Advances in lead-free alloy technology have also improved the mechanical properties of these solders, enhancing their hardness and durability to deliver high-quality, reliable joints.

However, lead-free solder does present certain challenges. It generally requires higher soldering temperatures, leading to increased energy consumption and a greater risk of heat-related damage to sensitive components. Additionally, lead-free solder tends to be more brittle than leaded variants, making it more susceptible to cracking particularly in thin layers when subjected to thermal cycling or mechanical stress.

Despite these limitations, the future of lead-free solder remains promising. Ongoing innovations are addressing current drawbacks, paving the way for improved performance and broader application across industries.

Specialized solder wire types: silver, flux core and more

Certain types of solder wire are designed for specialized purposes and tailored to meet the demands of various industries. For instance, silver solder wire is widely used in high-performance electronics and aerospace applications due to its excellent electrical and thermal conductivity. It also has a significantly higher melting point than standard solder, making it ideal for environments subject to thermal cycling, where strong and stable connections are essential.

This category often includes flux-core solder wire, which features a hollow center filled with flux. This built-in flux simplifies the soldering process by eliminating the need for separate flux application. Flux-core solder wire is especially valuable for on-site repairs or high-speed automated soldering, where efficiency and reliability are critical. Its use improves wetting performance, resulting in stronger, more dependable solder joints.

Additionally, specialized solder wires may be engineered with low melting points or formulated with unique alloys that offer enhanced mechanical strength or corrosion resistance. Each type must be precisely manufactured to meet specific performance expectations, ensuring that the final products are durable, high-quality, and capable of withstanding demanding operational conditions.

Advantages of Solder Wire

Solder wire offers several notable advantages compared to other soldering techniques, making it a preferred choice in various applications:

Well-suited for small-scale production runs

Ideal for soldering delicate or miniature components

Excellent for prototype development and testing

Practical for repair and maintenance tasks

Provides strong resistance to wear and degradation

Ensures good wetting properties, helping to minimize oxidation during the soldering process

Step-by-step guide to using Solder Wire efficiently

1. How to join wires using crimp terminals

- Grab your wire strippers and take about one centimetre of insulation off the end of your wire. Use your fingers to twist this nice and tight to avoid fraying.

- Match the colour coding on your crimp tool to the colour crimp terminal you are using and poke the bared wire end into the crimp terminal just far enough that none of the bare section is exposed, but not so far that none of the bared wire contacts the crimping area.

.png)

Squeeze the crimp tool to compress the crimp terminal around the wire.

Give the wire a gentle tug to ensure it is firmly locked in.

2. How to join wires using a soldering iron

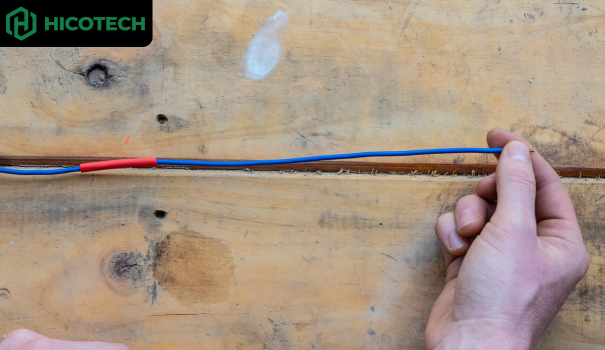

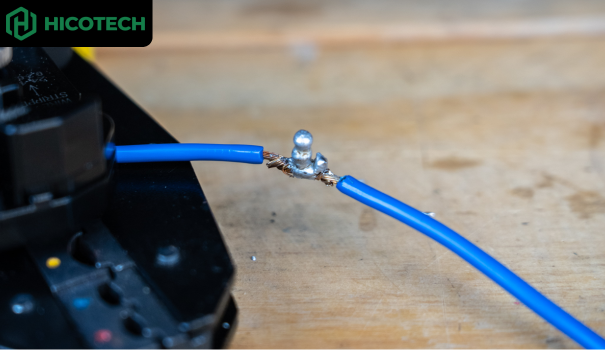

If you’re joining two wires, strip one to two centimetres of insulation from the end of each wire.

Slip a three-centimetre piece of heat shrink over the wire and push it at least ten centimetres from where you are wire joining.

Now make a cross with the bared ends and twist them together.

If you’re splicing into an existing wire, just use the strippers to bare a section in the insulation and twist the stripped end of your new wire around this.

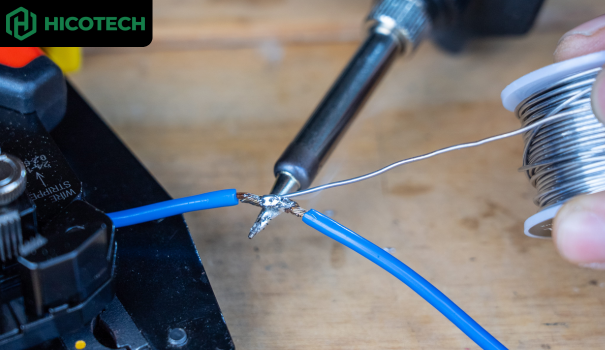

Allow the soldering iron to heat up for a couple of minutes. You know it’s ready when a touch of solder produces a puff of smoke.

Now apply a dab of solder to the tip. This is called “tinning”.

3. How to solder wires

Hold the tinned area of your soldering iron to your wire join for a few seconds.

Gently probe more solder right where the soldering iron meets the join.

The solder should flow through the join.

If it doesn’t melt, or it pools on top; allow the soldering iron to apply heat for a little longer and try again.

Once the solder join has cooled, you can slip the heat shrink over the join, and use the heat gun or blow torch to shrink it in place and insulate the join.

If you’ve spliced a join, it is usually impossible to apply heat shrink. Wrap the join in quality electrical tape instead.

How to choose the right Solder Wire

Selecting the most appropriate solder wire for your project involves evaluating several technical factors to ensure both efficiency and durability. Key considerations include:

Melting point: The solder wire’s melting temperature must align with the thermal tolerance of the materials being joined. For applications requiring high-temperature resistance, such as in aerospace silver solder is often preferred, as it melts between 700°F and 800°F, offering strong, heat-resistant joints.

Electrical conductivity: In high-density interconnect systems, excellent conductivity is essential to minimize signal loss and enhance device performance. Solder wires containing silver or gold alloys are ideal for such scenarios due to their superior electrical conductivity.

Tensile strength: The solder joints must be mechanically robust to endure operational stress, vibrations, or physical loads. Solder wires with added copper or nickel provide enhanced tensile strength, forming durable joints that resist mechanical wear.

Flux type: The type and activity level of flux within the solder wire significantly impact joint quality. No-clean, low-residue flux is ideal for applications where post-solder cleaning is impractical, while heavily oxidized surfaces may require a more aggressive flux for proper bonding.

Corrosion resistance: In harsh or corrosive environments, solder wires must resist degradation over time. Incorporating elements such as tin or zinc the alloy improves corrosion resistance, thereby extending the lifespan of the solder joint.

Cost efficiency: While high-performance alloys are engineered to function reliably under demanding conditions, cost is also a crucial factor. It’s important to balance performance requirements with budget constraints to a solder wire that delivers the best overall value for your project.

Common mistakes to avoid when selecting Solder Wire

When selecting solder wire for electronic applications, careful consideration is essential to avoid mistakes that could compromise performance. One of the most critical factors is the solder alloy’s composition and melting point. Ignoring these aspects can lead to weak or faulty solder joints and may even damage sensitive components due to excessive heat.

Equally important is the choice of flux material. Using an inappropriate flux can result in poor wetting, leading to weak, unreliable connections. The flux must be suitable for both the materials being joined and the specific requirements of the task.

Another common oversight is failing to ensure compliance with environmental regulations such as the RoHS directive. Using solder wire with high lead content in regions where lead is restricted can render products non-compliant and unsuitable for the market.

To make the best choice, it is vital to evaluate the project’s technical needs, material compatibility, and regulatory requirements. Thoughtful selection of the right type of solder wire not only ensures optimal performance but also supports product reliability and compliance.

Applications of Solder Wire

Solder wire is widely utilized across a broad range of industries, particularly in electronics and electrical engineering. In the consumer electronics sector, it is essential for securing components on circuit boards in devices such as smartphones, televisions, and computers. In the automotive industry, solder wire ensures dependable electrical connections in systems like sensors and control modules. The telecommunications field also relies on solder wire to maintain stable signal transmission within network infrastructure and communication devices. In industrial settings, it is used to join components in machinery and control systems, supporting reliable and consistent performance. These diverse applications highlight the critical role of solder wire and underscore the importance of advancing technology to enhance both its efficiency and effectiveness across various domains.

How to maintain Solder Wire for long-term use

Proper care and handling of solder wire are essential for ensuring its longevity and consistent performance. To prevent oxidation especially in humid environments it’s important to store solder wire in a dry, controlled setting. Regular inspection of the wire helps identify signs of contamination, corrosion, or heat damage to the outer layer, all of which can negatively affect soldering quality.

Before use, cleaning the solder wire with a suitable solvent can help remove dust or surface debris, reducing the risk of poor solder joints. It’s also recommended to follow the "first-in, first-out" (FIFO) inventory method to ensure older stock is used before newer supplies, minimizing the risk of degradation over time.

By implementing these storage and maintenance practices, you can extend the shelf life of your solder wire and maintain optimal performance throughout its use.

Có 0 bình luận, đánh giá về What is Solder Wire? Step-by-step guide to using solder wire efficiently

TVQuản trị viênQuản trị viên

Xin chào quý khách. Quý khách hãy để lại bình luận, chúng tôi sẽ phản hồi sớm