Heat Transfer Fluids for Data Center Immersion Cooling

Why Use Heat Transfer Fluid?

Data centers serve as the foundation of the digital era, enabling the storage, processing, and transfer of massive quantities of data. As the demand for more computing power and greater energy efficiency rises, traditional air-based cooling methods are increasingly struggling to keep up. Immersion cooling, a technique that involves submerging servers in a dielectric fluid, is emerging as a promising alternative.

At the heart of immersion cooling systems is the heat transfer fluid (HTF), which plays a vital role. This non-conductive liquid allows for the efficient dissipation of heat from servers and other electronic components, far surpassing the effectiveness of conventional air cooling methods. HTF acts as a medium that absorbs heat from the electronics and carries it away.

Cooling accounts for a significant portion of energy consumption in data centers, which already use enormous amounts of power. Immersion cooling, powered by HTF, offers a more sustainable solution, reducing the energy required for cooling. The improved heat dissipation minimizes energy consumption, leading to substantial cost savings. Furthermore, lower operating temperatures allow servers to perform more efficiently, resulting in reduced power usage overall.

Here’s how HTF typically functions in data center immersion cooling:

-

HTF Selection - The appropriate heat transfer fluid is chosen based on factors such as its specific heat capacity, thermal conductivity, and compatibility with electronic components. Common options include mineral oils, synthetic fluids, or specially engineered dielectric liquids that don't conduct electricity.

-

Component Submersion - Servers or individual components like processors and GPUs are immersed in tanks or baths filled with HTF. The fluid completely envelops these components, ensuring direct contact with their surfaces.

-

Heat Absorption - As electronic components operate and generate heat, the HTF absorbs the thermal energy from the hot surfaces.

-

Heat Transfer - The HTF, now heated, moves away from the hot components toward cooler parts of the system. This circulation can occur naturally through convection or with the aid of pumps.

-

Heat Dissipation - Once the HTF reaches a heat exchanger or cooling unit, the heat is transferred to a secondary medium, such as water or air. This medium then carries the heat away from the system.

-

HTF Circulation - After cooling, the HTF is recirculated back to the immersion tanks to begin the cycle again. This continuous circulation ensures that heat is efficiently transferred and dissipated, maintaining optimal cooling performance.

In summary, HTF-driven immersion cooling is a highly effective method that can significantly improve energy efficiency in data centers while reducing operational costs.

High-Quality Heat Transfer Fluids for Server Cooling

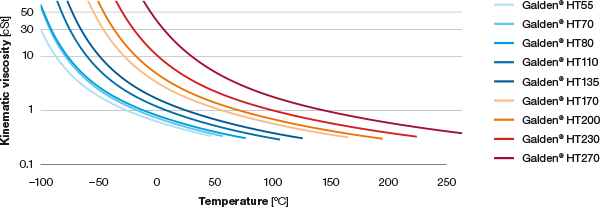

Galden® PFPE enhances IT performance by up to 8% compared to other fluorinated fluids, enabling faster computing. It is non-flammable, with no flash point, has FM Standard 6930 approval, and presents no risk of auto-ignition, explosion, or burning, even when exposed to open flames. This fluid boasts high dielectric strength, low dielectric constant, high resistivity, and MIL compliance. It is highly compatible with a wide variety of plastics, metals, and elastomers, while also being non-toxic and fully recyclable.

Galden® PFPE offers superior server cooling with no formation of deposits, no decomposition residues, and no risk of circulation pump seizure caused by fluid degradation or corrosion. It delivers precise temperature control, a wide range of grades to optimize performance, and high-boiling grades to reduce evaporation losses without compromising efficiency, ensuring safe operation even at elevated temperatures.