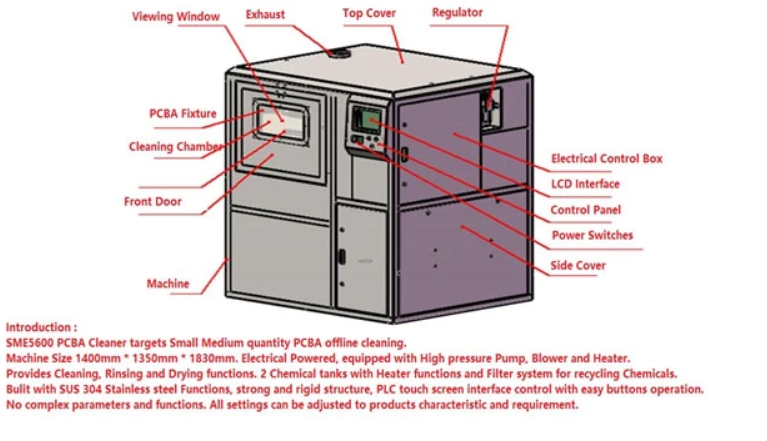

Product Description-PCBA Cleaning Machine SME 5600

The PCBA Cleaning Machine SME 5600 is an advanced and versatile cleaning solution specifically designed for small and medium-sized enterprises involved in electronics manufacturing. Here are its key features:

- Precision Cleaning

- Versatility

- Process Optimization

- Environmental Friendly

- User-Friendly Interface

- Reliability and Durability

This state-of-the-art machine ensures the thorough cleaning of printed circuit board assemblies (PCBAs), eliminating contaminants and residues that can impact their performance and reliability.

Technical datasheet of PCBA Cleaning Machine SME 5600 TDS

| Categories | PCB/PCBA cleaning machine |

|---|---|

| Brand | SAMTRONIK |

| Model | SME-5600 |

| Cleaning basket size | 610mm(L)*560mm(W)*100mm(H)x 2 layers |

| Concentration liquid tank capacity | 30L |

| Dilution tank capacity | 60L |

| Spray tank capacity | 18L |

| FOB port | Shenzhen |

| Terms of Payment | L/C, D/A, D/P, Western Union, T/T |

| Update Time | July 12,2023 |

Application of PCBA Cleaning Machine SME 5600

The PCBA Cleaning Machine SME 5600 offers a range of applications across various industries where the cleaning and maintenance of printed circuit board assemblies (PCBAs) are crucial. Here are some key applications:

1. Electronics Manufacturing

This product is an essential tool for electronics manufacturers, ensuring the cleanliness and reliability of PCBAs. It effectively removes flux residues, solder balls, and other contaminants that may impact the functionality and performance of electronic devices. It is widely used in the production of consumer electronics, such as smartphones, laptops, gaming consoles, and home appliances.

2. Automotive Industry

In the automotive sector, PCBAs are extensively used in vehicle electronics, including engine control units (ECUs), infotainment systems, and safety features. The SME 5600 is instrumental in maintaining the integrity of these critical components, removing dust, oils, and debris that could affect their performance and longevity.

3. Medical Device Manufacturing

Medical devices demand the highest levels of cleanliness and sterility. The SME 5600 ensures the removal of contaminants PCBAs used in medical equipment such as diagnostic devices, patient monitoring systems, and surgical instruments. It plays a crucial role in meeting stringent regulatory requirements and ensuring the reliability of these life-saving devices.

4. Aerospace and Defense

The aerospace and defense industries rely on highly reliable and durable PCBAs for avionics, communication systems, and military equipment. The SME 5600 helps in the maintenance and cleaning of these critical components, ensuring optimal performance and minimizing the risk of failure in demanding environments.

5. Industrial Control Systems

Industrial control systems employ PCBAs for automation, monitoring, and control of various industrial processes. This equiment aids in keeping these systems free contaminants, ensuring their smooth operation and preventing malfunctions that could result in costly downtime and production losses.

6. Renewable Energy

The production of renewable energy technologies, such as solar panels and wind turbines, involves the use of PCBAs. The SME 5600 helps maintain the efficiency and reliability of these components by removing dirt, dust, and residues that could hinder their performance.

7. Telecommunications

The telecommunications industry relies on PCBAs for the manufacturing of communication devices, network equipment, and infrastructure. This product plays a vital role in ensuring the cleanliness of these components, improving signal integrity, and reducing the risk of malfunctions.

In summary, this equipment finds applications across diverse industries where the cleanliness and reliability of printed circuit board assemblies are critical.

How to use PCBA Cleaning Machine SME 5600

Using the PCBA Cleaning Machine SME 5600 is a straightforward process. Here's a step-by-step guide on how to use the machine effectively:

1. Preparations

- Ensure that the machine is properly installed and connected to the necessary utilities, such as power and water supply.

- Familiarize yourself with the machine's user manual and safety instructions.

- Gather the PCBAs that require cleaning and inspect them for any visible contaminants or residues.

2. Loading the PCBAs

- Open the machine's loading chamber or conveyor system.

- Carefully place the PCBAs the loading area, ensuring they are properly aligned and spaced to avoid collisions during the cleaning process.

- Close the loading chamber securely.

3. Selecting Cleaning Parameters

- Power on the SME 5600 and allow it to initialize.

- Access the machine's control panel or interface.

- Set the desired cleaning parameters based on the specific requirements of your PCBAs. This may include parameters such as cleaning time, temperature, and detergent concentration.

- Consult the machine's user manual or seek guidance the manufacturer for recommended cleaning settings for different types of contaminants and PCBAs.

4. Initiating the Cleaning Process

- Once the cleaning parameters are set, start the cleaning process by pressing the appropriate start button or initiating the cleaning sequence through the control panel.

- The machine will begin the cleaning cycle, which typically involves spraying a cleaning agent or solvent onto the PCBAs and using various mechanisms, such as high-pressure nozzles or brushes, to remove contaminants.

- Monitor the progress of the cleaning process through the machine's display or indicators.

5. Post-Cleaning Inspection

- After the cleaning cycle is complete, open the machine's unloading chamber or conveyor system.

- Carefully remove the cleaned PCBAs the machine.

- Inspect the PCBAs visually to ensure that contaminants have been effectively removed. Check for any remaining residues or signs of damage.

6. Drying (if applicable)

- Depending on the machine's capabilities, you may have the option to perform a drying step after the cleaning process to remove moisture the PCBAs.

- If drying is required, follow the machine's instructions to activate the drying function and allow the PCBAs to dry completely before further handling or assembly.

7. Post-Cleaning Quality Assurance

- If necessary, perform additional quality assurance tests on the cleaned PCBAs to ensure they meet the desired standards of cleanliness and functionality.

8. Maintenance and Cleaning of the Machine

- After each use, follow the manufacturer's instructions for cleaning and maintaining the SME 5600. This may involve cleaning filters, removing debris, and ensuring the proper functioning of the machine's components.

Always refer to the specific user manual and guidelines provided by the manufacturer of the product for detailed instructions and safety precautions.

Where to buy PCBA Cleaning Machine SME 5600?

HicoTech - authorized dealer of SAM TRONIK in Vietnam, is committed to providing genuine products, ready to assist customers in product installation and provide detailed user manuals. In addition, we also commit to a full warranty according to the company's regulations, ensuring that customers have peace of mind and satisfaction with the product they have purchased.

Contact Info:

Hotline / Zalo: 0945 261 931

Email: sale@hicotech.com.vn

Có 0 bình luận, đánh giá về PCBA Cleaning Machine SME 5600

TVQuản trị viênQuản trị viên