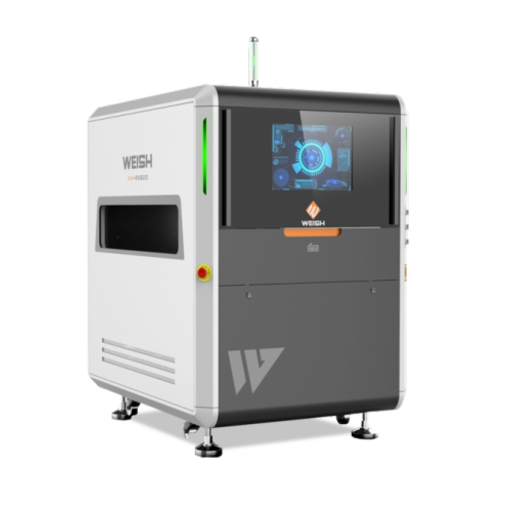

SMT online AOI WS-AS510 is a WEISH product manufactured by DongGuan WEISH Electronic Technology Co.,Ltd, Dongguan, China. WEISH online AOI WS-AS510 series are suitable for high-precision and high-speed inline inspection of both pre-reflow and post-wave.

Product Features of SMT online AOI WS-AS510:

☆ Use of granite platform and telecentric lens.

☆ Powerful software algorithm makes inspection very reliable.

☆ Automatic compensation for board warpage , deformed by high temperature effects

☆ SPC data analysis helps to improve process quality

Features & Functions of SMT online AOI WS-AS510:

☆ Three point Check

Software that connects SPI, pre-reflow AOI and post-reflow AOI for data collection helps to quickty locate the root cause of the defects

SPC Alarm Function

Real-time production quality monitoring can be achieved thru’ timely feedback of abnormal situation, thus, preventing defects flowing thuru

☆ Output Entire Board photo

The entire board photo of component or non-component area can be saved fof the quality traceability purpose after the inspection is completed

☆ Automatic program Switch Through Barcode Scanning

Auto width adjustment is a standard feature and is achieved by simply reading the PCB ‘s barcode, At the same time, it supports MES command..

☆ Major Defects fool proof

This feature can be set up by an authorized personnel to specifically inspect key tocations.This will prevent unauthorized individuals allowing a bypass of such a location to be inspected, Such a feature helps ensure good control over critical locations to be inspected

☆ Multiple Repair Stations can be linked to a Single Repair Station

One operator can handle multiple machines repair stations, thus, improving the repair process and saving manpower

Core Technology and Advantages of SMT online AOI WS-AS510:

☆ Intelligent Solder Pad positioning + Entire FOV Assisted positioning

With the use of proprietary Solder Pad Positioning we cansignificantly reduce false calls caused by deformation of PCB after wavesoldering. This is even more pronounced for FPC. Our entire FOV assistedpositioning algorithm also helps to significantly reduce false calls due to PCBwarpage, silkscreen printing and interference caused by the board's legend.

☆ Poor Soldering Inspection

Based on precise positioning of the solder pad poor solder of chip or IC can be effectively detected.

☆ Detection Parameters Directly Interface With IPC Standards

Our algorithm can calculate offsets based on IPC standards resulting in more reliable inspection.

Maximum Component Side Overhang (IPC-A-610-G Class 3) :Less than 25% of the component termination width or 25% of thepad width whichever is less

Product Specification of SMT online AOI WS-AS510:

|

Product Model |

WS-AS510 |

|

|

Image System |

Camera |

5MP/12MP Pindustrial camera |

|

Resolution |

5MP camera: 15μm, 10μm; 12MP camera: 15μm, 12μm, 10μm, 6.3μm |

|

|

FOV |

3730mm( 5MP, 15μm); 6045mm(12MP,15μm) |

|

|

Lens |

Telecentric lens |

|

|

Lighting |

4 color ring shape LED (RGBW) |

|

|

Movement Structure |

X/Y Movement |

AC Servo |

|

Platform |

Granite |

|

|

Width Adjustment |

Automatic |

|

|

Transport Type |

Belt |

|

|

Board Loading Direction |

→Right or Right→(at point of order) |

|

|

Fixed Rail |

Single Lane: 1st fixed rail; Dual Lane: 1st rail ( 1st & 3rd fixed rail or 1st & 4th fixed rail) |

|

|

Hardware Configuration |

Operating System |

Win 10 |

|

Communication |

Ethernet, SMEMA |

|

|

Power Requirement |

Single phase 220V,50/60Hz,5A |

|

|

Air Requirement |

0.4-0.6Mpa |

|

|

Conveyor Height |

900±20mm |

|

|

Equipment Dimensions |

L1170D16081580mm(without tower light) |

|

|

Equipment Weight |

900Kg |

|

|

PCB Size |

Size |

5060-510610mm |

|

Thickness |

0.6-6.0mm |

|

|

PCB Weight |

≤3kg |

|

|

Component Clearance |

Top clearance 25-60mm adjustment, Bottom clearance 45mm |

|

|

Clamping Edge |

3.0mm |

|

|

Inspection Criteria |

Component |

Wrong chip, Missing chip, Chip reverse, Chip deviation, Rotation, Chip flip, Solder bridge, Foreign material, Solder ball |

|

Lighting Detection |

Too bright, Too dark, Not bright |

|

|

Solder Joint |

No Solder, Insufficient Solder, Open Solder , Excess Solder, Solder Bridge, Solder Ball, etc. |

|

|

Component Size |

Chip: 03015 and above; LSl: 0.3mm pitch and above; Others: Odd shape component |

|

|

Inspection Speed |

180-200ms/FOV |

|

Currently, Hicotech is operating as a distribution agent for genuine WEISH products in Vietnam. Along with a technical team that advises and answers all customer questions related to the product, Hicotech is committed to providing customers with high quality products and the best support service on the market.

Contact Info:

Hotline / Zalo: 0945 261 931

Email: sale@hicotech.com.vn

.PNG)

Có 0 bình luận, đánh giá về SMT online AOI WS-AS510

TVQuản trị viênQuản trị viên