HumiSeal 2E10-B Drescription

HumiSeal 2E10-B is a two-component product, consisting of the 2E10-B coating and the 2E40 hardener. When these two components are mixed together, they create a robust and durable protective coating. Its characteristics include:

- Mechanical Strength: Provides strong mechanical protection, enhancing the durability of electronic components.

- Waterproofing and Moisture Resistance: Offers resistance against water and moisture, safeguarding sensitive electronics environmental elements.

- Insulation Properties: Acts as an effective insulator, preventing electrical conductivity and potential short circuits.

- RoHS Compliance: Meets the RoHS (Restriction of Hazardous Substances) standards, ensuring safety and environmental compliance.

HumiSeal 2E10-B finds extensive application in both the industrial and electronic sectors, serving to shield electronic circuits and components environmental factors and mechanical stresses.

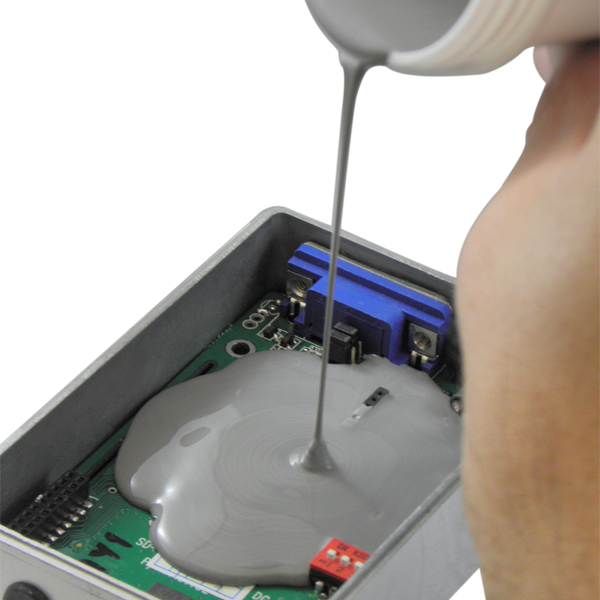

Application of HumiSeal 2E10-B encapsulant

- Cleanliness of the substrate is of extreme importance for the successful application of HumiSeal 2E10-B. Surfaces must be free of moisture, dirt, wax, grease, flux residues and all other contaminants.

- Encapsulants can be successfully applied to substrates that have been cleaned prior to coating and also to substrates assembled with low residue “no clean” materials.

- Users should perform adequate testing to confirm compatibility between the encapsulants and their particular assembly materials, process conditions and cleanliness level.

- HumiSeal 2E10-B is an epoxy potting compound with extended work life suitable for electronic applications. The two-part system mixes in an easy 1:1 ratio and cures easily to form a rigid black encapsulant.

- HumiSeal 2E10-B provides excellent environmental and chemical resistance with a high dielectric strength of 550 V/mil.

Using HumiSeal 2E10-B for:

Here are some common applications of HumiSeal 2E10-B:

- Industrial Electronics: Used to protect electronic circuits in industrial devices such as industrial computers, measurement and control equipment, communication devices, and other industrial electronic circuits.

- Automotive Industry: Applied to safeguard electrical circuits and components within lighting systems, control systems, dashboards, engine systems, and entertainment systems of automotive vehicles.

- Medical Devices: In the medical field, this coating is utilized to protect electronic circuits and components in medical devices like diagnostic equipment, monitoring devices, and mobile medical tools.

- Telecommunications: Employed in telecommunication devices, including communication equipment, network devices, and mobile communication tools, to shield electronic circuits and components environmental influences and mechanical impacts.

- Electronic Manufacturing: Used to protect electronic circuits and components in electronic manufacturing devices such as printers, scanners, testing and measurement equipment, and industrial control panels.

This product can also find applications in other areas like consumer electronics, household appliances, renewable energy industry, and automated control systems.

Technical data HumiSeal 2E10-B

| Property | Value |

|---|---|

| Chemistry | Epoxy |

| Viscosity Part A (CPs) | 6,000 |

| Viscosity Part B (CPs) | 12,000 |

| Mix Ratio | 1:1 |

| Pot Life (min) | 60 |

| Handling Time (min) | 180 |

| Full Cure | 24 hr @ RT or 1 hr @ 65°C |

| Cure Type | 2 component with heat option |

| Color | Black |

| Hardness | D85 |

| Operating Temp (°C) | -50 to 155 |

| Applications | Industrial sealing, bonding, and encapsulation |

| Substrates | Metals, Glass, Ceramics, Plastics |

How to use HumiSeal 2E10-B ?

To use HumiSeal 2E10-B, you can follow these steps:

- Surface Preparation: Ensure that the surface of the electronic circuit or component is clean and dry before application. Remove dust, grease, or any contaminants that might affect the effectiveness of the coating.

- Mixing: Mix the 2E10-B coating and the 2E40 hardener according to the ratio specified by the manufacturer. Ensure thorough and even mixing to achieve a perfect combination of the two components.

- Application: Use suitable tools such as brushes, spray guns, or dispensing machines to apply the coating onto the surface to be protected. Ensure an even and thin coating to prevent localized thick spots or uneven coating.

- Drying: To allow the coating to dry completely, use a drying method or allow it to dry naturally in a well-ventilated environment. The specific drying time may vary depending on environmental conditions and the thickness of the coating.

- Testing and Inspection: After the coating has dried completely, assess its durability and effectiveness. Use appropriate testing and measurement equipment to ensure that the coating meets necessary requirements.

Note: Prior to usage, carefully read the manufacturer's instructions and safety information.

Where to buy authentic HumiSeal Thinner 904 ?

Thanks to our strong reputation, Hicotech has earned the trust of numerous customers. Feel free to reach out to us for expert consultation and to avail the best pricing for the HumiSeal Thinner 904 product.

Contact information

Hotline/Zalo. 094 526 1931

Website. Hicotech.com.vn

Email: Sale@hicotech.com.vn

Có 0 bình luận, đánh giá về HumiSeal 2E10-B

TVQuản trị viênQuản trị viên