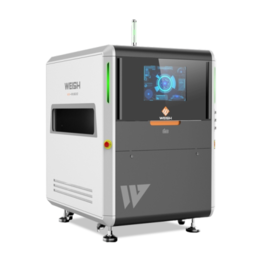

SMT SPI Machine

What is SPI in the SMT Process?

SPI stands for Solder Paste Inspection in the SMT (Surface Mount Technology) Process. The primary purpose of SPI is to inspect the application of solder paste on the PCB (Printed Circuit Board) during the manufacturing process.

The utilization of SPI serves a crucial role in identifying potential defects in the solder paste application early in the production cycle. By employing an SPI machine, errors can be detected before the PCB is populated, preventing the need for costly repairs that may arise if the issues are discovered later in the process. The machine's precision is vital, as it not only measures the length and width but also accurately assesses the height, volume, and area of the solder paste feature.

This early defect detection capability translates into significant time and cost savings. Consistent and accurate application of solder paste is paramount, and timely identification of any discrepancies is critical. The ability to measure the three-dimensional aspects of solder paste on the PCB enables early detection of issues, facilitating necessary adjustments to enhance PCB functionality. This proactive approach reduces rework requirements, ultimately improving profitability.

Advantages of SPI in SMT Processing:

-

In practical production, integrating SPI online inspection into the SMT patch line effectively lowers the rate of unqualified patch processing. This results in substantial cost reductions for repair and scrap, contributing to enhanced overall product quality.

-

Combining online SPI detection with online AOI (Automated Optical Inspection) detection provides real-time feedback and optimization for the SMT chip processing production line. This integration minimizes the duration of the unstable trial production stage, ensuring more stable and efficient production quality.

-

SPI helps significantly reduce the misjudgment rate of AOI inspections related to soldering, leading to improved pass-through rates. This reduction in errors enhances efficiency, saving both manpower and time costs associated with manual error correction.

Hicotech offers comprehensive electronic manufacturing services (EMS), including component sourcing, SMT component placement, through-hole assembly, box assembly OEM/ODM, providing a one-stop solution for your electronic manufacturing needs.